FACILITIES STRICT COMPLIANCE STANDARDS

Pristine Biologicals manufactures Adult Bovine Serum sourced from best breed pasture grazed New Zealand cattle from EU/ USDA approved premises. Our scientifically designed and purpose built GMP compliant plant facility delivers quality bovine serum production. Collection, handling, processing, containerization and storage meet strict regulatory compliance and understanding of end user requirements.

Safe sourcing, collection and processing in a protected environment are of great importance.

Bovine blood is collected only from EU/USDA approved abattoirs in closed method under hygienic conditions. All the operations are subject to daily independent verification by veterinarians employed by New Zealand Ministry for Primary industries (MPI).

Disease Free Premium Supply / Certifications

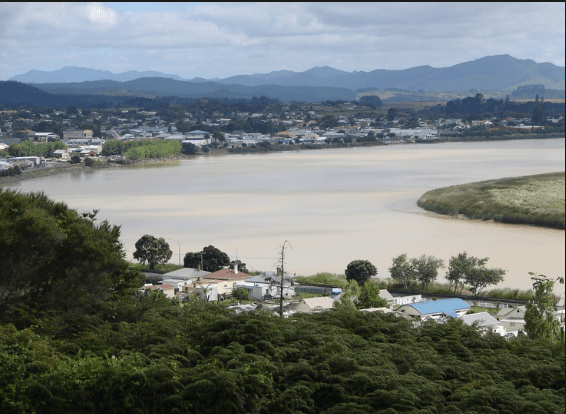

New Zealand's strict border controls and pasture based agricultural economy have ensured that this country remains free of scrapie, all list A (OIE) diseases and major animal diseases including TSE/BSE, Blue tongue, Foot & Mouth and Rinderpest.

Pristine Biologicals follows both internal quality systems and all New Zealand Ministry for Primary Industries (MPI) compliances for manufacturing and exports.

We provide export health certificates issued by MPI for all export consignments. Product release criteria includes quality testing at Pristine's in-house laboratory, MPI approved laboratories, and also at other International accredited laboratories for each batch/lot.

Direct Source Competitive Advantages

As a source manufacturer, Pristine Biologicals offers supply partners key strategic advantages.

Partners get source point competitive costings.

We produce bovine serum to industry standards. At source production, Pristine Biologicals has manufacturing and laboratory batch testing flexibilities for meeting varied customized client requirements for volume manufacturing.

Bovine Serum Collection

Bovine serum is the end product of bovine blood usually collected from animals at the time of slaughter. Blood collection from calves or adult cattle in slaughter house is performed under clean, controlled conditions. Blood is collected aseptically using equipment designed to protect the material from microbial contamination. The serum collection and processing is carefully monitored. The serum is separated from blood, processed, filtered, filled in containers and stored at -20°C. The serum manufactured under controlled conditions consistently meets all relevant rules and regulations and the specific requirements of the customer.

Bovine Serum Processing

Serum samples are tested using approved tests to confirm freedom from bacteria and other microorganisms. Appropriate biochemical and biological tests are performed. Gram negative bacteria produce toxins such as endotoxins that could be harmful. Only appropriate processing steps can assure freedom from such harmful substances. Viruses are common contaminants of serum and cannot be removed by sterile filtration methods. Track and trace system of each process step and the results of all testing performed provide complete data of each individual batch of serum that is supplied to the customer. In addition serum should be certified as BSE/TSE free. Sourcing of serum from BSE/TSE free regions, safe collection and processing in a protected environment are of great importance.